Not all machining companies have experience and expertise in working with all types of materials. Other companies may have a wide range of experience in working with different metals, alloys, and plastics as part of their precision or production CNC machining services.

When it comes to working with aluminum alloys, find a company with experience in aluminum machining is worth the time and effort. These companies know which aluminum alloys are best for machining and which tempers of aluminum are ideal for different types of machining.

Best Types of Aluminum

In the aerospace industry, in medical devices as well as the energy sector, including oil and gas production, aluminum is a key material. It has an exceptional strength to weight ratio and a high level of resistance to corrosion, with some variations based on the specific alloy.

There is a wide range of options for aluminum machining, with several of these alloys also considered good or excellent for weldability, corrosion resistance, strength, and heat treatment requirements.

Those alloys considered ideal for aluminum machining include 2011, 1100, 3003, 6061 and 7075, with the last two listed as good or fair based on the specific temper of if it is in an annealed condition.

Precision Work

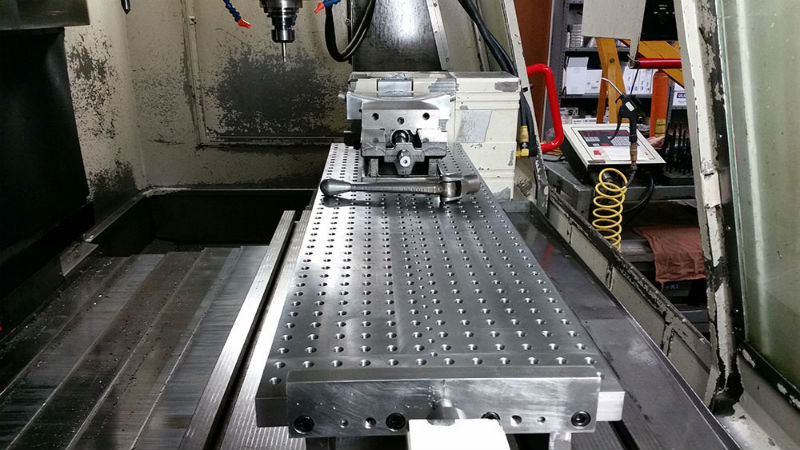

Experienced companies are able to machine aluminum parts and components to the exacting, precise tolerances required. This is only possible through the use of state-of-the-art machining equipment combined with engineers and equipment operators to manage the process.

Machining companies may also offer secondary or value-added types of services for aluminum parts and components. These services may include fabrication, assembly, deburring or bending of the parts or there may be other options in services offered.

Working with one company to complete all the work required on an aluminum part or component helps to reduce both production cost and time, while also making logistics and scheduling a much easier task.