If you need steel or aluminum bonded together, you can use a number of methods like spot, MIG, or TIG welding. However, plastic is not as easily welded because it has a lower melting point than metal. You could use several methods for bonding plastic, but with ultrasonic welding services, you enjoy a wide range of benefits. Here are some reasons to consider these services.

Bonding Plastic Methods

One of the most common methods for bonding plastic materials is gluing. You can place adhesives between the surfaces. However, you must use special adhesive made for non-porous materials like plastic. This is not the most cost-effective way to bond plastic because you have to keep using adhesive. Also, many adhesives create fumes or odors which can cause irritation to people. Ultrasonic welding services use no consumables like adhesive.

Fasteners

You can join plastics together with rivets or screws. This is the best for electronics and items which require taking apart. Yet, when you need a permanent bond, fasteners are not really necessary. Snap fittings work well, but they do not give you the strong bond ultrasonic welding services provide.

What Does Ultrasonic Mean?

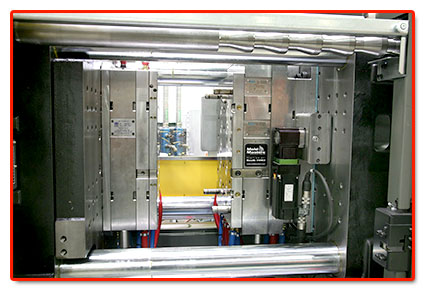

Typical welding methods would quickly melt or deform plastic. Unlike standard welds, ultrasonic methods do not require a heat source. Instead, they use sound waves which vibrate and generate heat between the two items you are bonding. It takes high-frequency vibrations to create the bond, and it is permanent.

Benefits

You can create very strong and permanent welds with ultrasonic methods. The process is easy to automate for greater efficiency, and it takes less than one second to complete. You can make hermetically sealed products which are tamper-proof. If you have heat-sensitive products, welding with sound waves is one of the most efficient and quickest methods you can use.